Custom-made expansion joints

Costruzione Ricambi Macchine Industriali based in Milan has been specialized for over fifty years in the construction of expansion joints.

These elements are designed to absorb the vibrations of motors, expansions and contractions of pipes due to the significant thermal differences and movements to which the systems are subjected, thanks to the flexibility of the bellow and the physical properties of the stainless steel from which the convolutions stand. Some applications for using expansion joints are industrial engines, generator sets, CHP systems, earth moving machines, hoods, water systems, suction systems, cooling systems, and other types of equipment.

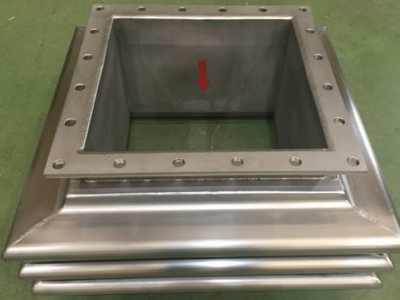

Costruzione Ricambi Macchine Industriali manufactures expansion joints in the required size with clamps and / or flanges according to the required dimensions. We are able to build them with variations in diameter and length of up to 0.5mm from standard sizes for maximum flexibility.

Some examples of custom-made expansion joints that we can make have flanges with diameters, holes, and center-to-center distances made to customer specifications. They can have a variable length and different ends (e.g. a swivel flange on one side, the welding ends on the other).

We develop and build the following compensators thanks to a careful analysis of the working conditions of the joint and the different types of deviations to which the bellows is subjected:

- axial

- angular

- lateral

- spherical lateral

- universal

- rectangular

Costruzione Ricambi Macchine Industriali designs and manufactures expansion joints by evaluating the conditions, the working conditions and all the other characteristics required to size the expansion joints in order to offer their customers the most optimal solutions for their needs. We test the bellows of our expansion joints according to the EJMA standards and the clamps according to the European standard UNI EN 13445.

Our tests

The expansion joints are monitored during each phases of construction: the construction of the bellows, ends and assembly. These items, in addition to careful dimensional and visual control, are tested with pneumatic and/or hydraulic test. We can also carry out the control of the penetrant liquids on customer request.

Contacts