Costruzione Ricambi Macchine Industriali

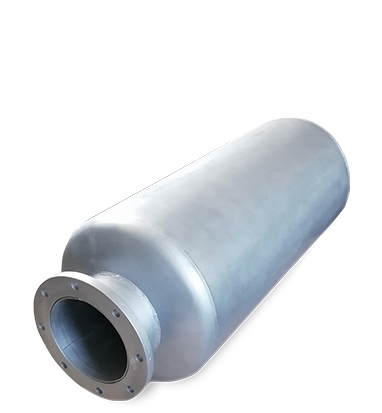

Compensatori di dilatazione, particolari per tubazioni, silenziatori industriali a Milano dal 1968.

Massima flessibilità produttiva.

Contattaci

L'Azienda

Da oltre 50 anni nel settore industriale

Costruzione Ricambi Macchine Industriali progetta e produce a Milano da oltre 50 anni compensatori di dilatazione per diverse applicazioni, tubi di scarico e altri apparecchi per tubazioni. Realizziamo anche silenziatori industriali e altri articoli per impianti in ambito industriale e civile. Offriamo una grande flessibilità produttiva: realizziamo sia prodotti a catalogo che prodotti personalizzati e su misura.

Scopri di piùServizi

Offriamo ai nostri clienti il servizio di carpenteria leggera a Milano e non solo,, assicurando la massima flessibilità e garantendo un ampio ventaglio di soluzioni e possibilità di realizzazione.

Scopri i nostri servizi